A Homeowner’s Guide to Roof Replacement Scope

How to Use This Guide: Outline, Planning, and Why Scope Matters

Your roof does more than keep rain off your head—it regulates energy, protects structure, and anchors curb appeal. When it’s time for replacement, a clear scope is the difference between a smooth project and a series of costly surprises. This guide gives homeowners a practical roadmap to evaluate three core factors that drive effort, materials, time, and budget. Along the way, you’ll find examples, simple calculations, and checklists you can borrow for your own project. Think of this as your pre-job compass before any shingle is removed or a single dumpster touches the driveway.

Here’s the outline we’ll follow, so you can jump to what you need or read it straight through:

– Factor 1: Roof Size and Pitch — how to measure area, adjust for slope, account for waste, and understand what pitch means for crew safety and schedule.

– Factor 2: Choice of Roofing Materials — a side-by-side look at weights, durability, fire ratings, energy performance, acoustic qualities, and regional suitability.

– Factor 3: Condition of the Existing Structure — how decking, framing, ventilation, and flashing influence tear-off decisions and add-on work.

– Logistics and Timeline Touchpoints — staging, access, weather windows, and neighborhood considerations.

– Conclusion and Next Steps — a homeowner checklist to finalize scope, compare bids, and plan the first day on site.

Why scope matters comes down to four levers:

– Cost: Area and complexity determine labor hours; materials and structural fixes shape the invoice.

– Time: Pitch, penetrations, and weather windows govern how many crew-days you’ll need.

– Risk: Hidden rot, under-ventilation, or overweight materials can stress framing if not addressed.

– Performance: Matching materials and details to climate and code elevates longevity and comfort.

As you read, keep a simple folder of notes: a sketch with measurements, a photo log of trouble spots, and a running list of must-haves (ice barrier at eaves, upgraded ventilation, new flashings). By the end, you’ll be ready to request apples-to-apples proposals, set expectations on disposal and cleanup, and choose options that fit your home’s climate and your priorities. Think of scope as the story of your roof replacement; the clearer the story, the better the ending.

Factor 1: Roof Size and Pitch

Size and pitch form the backbone of any roofing scope. Roof area is usually quoted in “squares,” where 1 square equals 100 square feet of roof surface. A quick way to estimate area is to start with the building’s footprint and then adjust for slope and overhangs. For a simple gable roof, area ≈ footprint × slope factor. Common slope factors derived from basic geometry include: 4:12 ≈ 1.054, 6:12 ≈ 1.118, 8:12 ≈ 1.202, and 12:12 ≈ 1.414. These factors reflect how the roof surface grows as pitch increases.

Example: A 40 ft × 30 ft home has a 1,200 sq ft footprint. With a 6:12 pitch, 1,200 × 1.118 ≈ 1,342 sq ft. Add, say, 2 ft overhangs on all sides (approx. 15% more), giving about 1,543 sq ft. Include waste (starter, ridge, cut-offs) of 7–15% depending on complexity; at 12%, that’s 1,728 sq ft, or roughly 17.3 squares. A hip roof or one with dormers, valleys, and skylights typically runs higher waste—often 12–20%—because cutting and flashing around features consume material and time.

Pitch also drives safety and production rates. Low-to-moderate slopes (3:12 to 6:12) allow faster tear-off and installation, while steep slopes (8:12 and above) often require additional fall protection, toe-boards, staging planks, or temporary anchors, all of which slow progress. A small crew might complete 18–25 squares per day on simple, walkable roofs, but steep, cut-up roofs may drop to 8–15 squares per day. That difference affects both schedule and labor cost.

Access is another variable tied to size and pitch. Delivering materials to a high ridge may require a lift or conveyor. Limited driveway space or soft soil can complicate dumpster placement and underlayment staging. Multiple levels (e.g., a one-story garage tied to a two-story main roof) increase ladder moves and safety setups, adding hours that don’t show up in the raw square count.

To scope accurately, gather the following:

– A sketch with rough dimensions, noting overhang widths.

– Slope measurements from a simple level-and-tape method or a digital inclinometer.

– A count of penetrations (vents, stacks), linear feet of ridges/hips/valleys, and any walls needing step flashing.

– Notes on access: gate widths, tree clearances, and parking.

With these basics, estimates align more closely with reality, and change orders become the exception rather than the rule.

Factor 2: Choice of Roofing Materials

Materials shape everything: structural loads, labor methods, weather resilience, and how your home handles heat and noise. While selections vary by region and code, common residential options include asphalt shingles, metal panels, composite shingles, wood shakes, concrete or clay tile, and natural slate. Each carries different weights, lifespans, and maintenance profiles, and those differences ripple through your scope.

Weights (approximate, installed):

– Asphalt shingles: ~2.0–2.5 lb/sq ft

– Steel or aluminum panels: ~0.9–1.5 lb/sq ft

– Wood shakes: ~3–4 lb/sq ft (varies with moisture)

– Concrete/clay tile: ~9–12 lb/sq ft

– Slate: ~8–12+ lb/sq ft

Heavier systems may require engineering review to confirm framing capacity, especially for retrofits on older homes. In snow country, combined dead load (roofing) plus live load (snow) must stay within design limits; materials that add 8–12 lb/sq ft can be transformative and may trigger structural reinforcement in certain cases.

Durability and performance:

– Asphalt shingles are versatile, with many Class A fire-rated options and wind ratings that suit a wide range of climates. Typical service life varies with grade and climate.

– Metal panels offer long service lives, excellent shedding of snow, and high reflectivity when finished in “cool” colors. Sound can be mitigated with solid decking and underlayment.

– Composite products mimic slate or shake at lower weight; quality varies, so review test data for impact and fire ratings.

– Wood offers a classic texture but may require more maintenance, and some regions restrict use in wildland-urban interface zones due to fire risk.

– Tile and slate deliver exceptional longevity with proper underlayment and fastening systems, but their weight and installation complexity require careful planning.

Energy and comfort: Solar reflectance and ventilation matter. Lighter colors and reflective coatings can reduce attic temperatures. Balanced intake and exhaust ventilation (often 1:150 net free vent area to attic floor area, or 1:300 where a continuous vapor barrier exists, per many codes) reduces moisture and improves shingle longevity.

Underlayment and flashings are part of the material conversation. Synthetic underlayments resist tearing and dry quickly; self-adhered ice and water barriers at eaves and valleys reduce leak risk in freeze-thaw climates. Metal flashings at edges, walls, chimneys, and skylights are a small cost with large benefits. Ridge vents paired with soffit vents enhance airflow; without adequate intake, exhaust alone underperforms.

Budget signals: Installed costs vary widely by region and roof design, but a general hierarchy is common—many asphalt systems sit at the lower end, metal and composite occupy the mid-to-high range, and tile or slate trend higher due to labor and structure demands. Always compare full system quotes (shingles/panels, underlayment, flashings, ventilation, fasteners) to avoid “low-number” bids that quietly omit key components. A material isn’t just a finish; it’s part of a system that should match your climate, structural capacity, and maintenance appetite.

Factor 3: Condition of the Existing Structure

The state of what lies beneath your current roof can expand or streamline scope. Decking, framing, ventilation, and flashing details determine whether a project is a straightforward tear-off-and-replace or an involved rehabilitation. Start with a condition assessment: look from the attic and the exterior. Inside, use a flashlight to spot daylight at joints, water stains on sheathing, or dark fungal blotches. Outside, note soft spots underfoot, sagging ridgelines, or ripples that telegraph delamination.

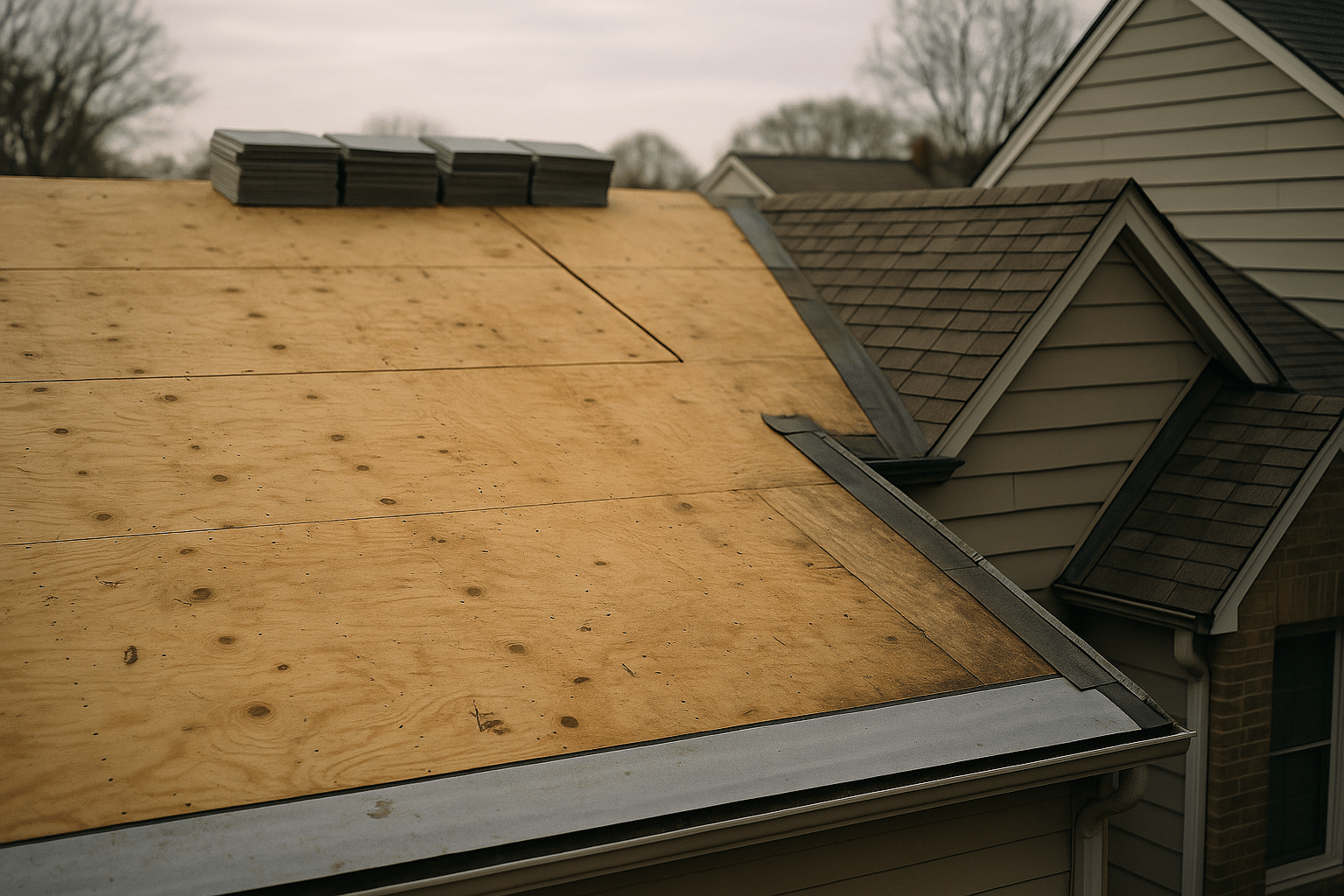

Decking matters. Many homes use 7/16 in OSB or 1/2 in plywood; older structures may have 1x boards with gaps. If nails miss solid wood or withdraw easily, expect sheathing replacement. Localized repairs of 5–15% are common on roofs with long leak histories, but full re-sheathing is sometimes warranted where rot is extensive or the substrate is too uneven for modern materials. H-clips between panels (where applicable), proper gapping, and correct fastener schedules improve stiffness and shingle laydown.

Framing and loads: Rafters or trusses should be checked for cracks, water damage, or sistered repairs. In heavier material upgrades (tile, slate), an engineer may verify spans and connections. Snow-prone zones and regions with high wind uplift have additional fastening requirements that can affect scope, such as more nails per shingle, ring-shank fasteners, or enhanced underlayment in designated areas. Addressing these at the planning stage prevents rushed, mid-project choices.

Ventilation and moisture control are durable roof essentials. Inadequate intake or blocked baffles can trap moisture, shorten roofing life, and foster mold. Balanced airflow (soffit plus ridge or equivalent) and sealed penetrations help the assembly dry as it should. Bathrooms and kitchens should vent outdoors, not into the attic. If you change ventilation type—say, to a continuous ridge vent—close off old box vents to avoid short-circuiting airflow.

Flashings and transitions: Chimneys, skylights, step flashing at sidewalls, and headwall flashings are frequent leak points. Reusing old flashings to save a little up front can invite callbacks later. A thorough scope typically includes new metal flashings, kick-out diverters where siding meets roof edges, and proper counterflashing at masonry.

Overlay vs. tear-off: Some jurisdictions allow one additional roofing layer; however, overlays can mask underlying damage, add weight, and trap heat. Tear-off exposes the deck for repair, improves fastener hold, and resets your waterproofing layers. When in doubt, a full tear-off paired with a targeted repair allowance in the contract keeps surprises manageable.

Signs that add scope:

– Chronic leaks or ceiling stains near valleys or chimneys.

– Spongy decking underfoot or pervasive nail pops (“shiners”).

– Attic frost in winter or musty odors year-round.

– Visible gaps around vents, loose flashing, or failing sealant.

Any one of these can shift your project from a simple re-roof to a repair-and-replace plan.

Conclusion and Next Steps: Turning Findings into a Clear Scope

By now, you’ve seen how three factors—size and pitch, materials, and existing conditions—shape the real-world effort behind a roof replacement. The goal isn’t to become a roofer overnight; it’s to translate observations into a clean scope contractors can price accurately. Think of it like packing for a long trip: the better the list, the fewer detours. A crisp scope also makes it easier to compare proposals without getting lost in jargon or line-item gaps.

Build your scope checklist:

– Measurements: total squares, slope by plane, linear feet of ridges/hips/valleys, and count of penetrations.

– System choices: roofing type and color family; underlayment (synthetic plus ice barrier at eaves/valleys where climate warrants); metal flashings at all edges and walls; ridge and soffit ventilation targets.

– Structural items: decking repair allowance (e.g., include the first 5–10 sheets at no charge, then a per-sheet rate), framing evaluation if changing to heavier materials.

– Site logistics: dumpster location, material delivery method, protection of landscaping, daily cleanup routine, and rain contingency plan.

– Warranty notes: material warranty registration and written workmanship coverage with point-of-contact for follow-up.

Request apples-to-apples proposals by including the same scope with each bid. Ask bidders to identify exclusions plainly (e.g., skylight replacement, chimney repair, or gutter work). If estimates differ widely, look for variances in waste factors, underlayment types, or ventilation details. A slightly higher quote that includes essential components often yields fewer callbacks and stronger performance over time.

Before day one, walk the property: photograph pre-existing conditions, move patio furniture, mark sprinkler heads, and discuss start times and staging zones. Confirm weather windows and how the crew will secure the roof if a sudden storm rolls through. Small planning steps are like good flashing details—quiet, unglamorous, and remarkably effective.

Final thought: your roof is your home’s weather jacket, and the seams matter as much as the fabric. With a defined scope, you can choose materials that suit your climate and structure, schedule work during reliable weather, and invite proposals that respect both your budget and your time. Clarity now pays dividends for decades above your head.